新着情報

- 2025年4月16日お知らせ中小企業優秀新技術・新製品賞を受賞しました

- 2025年4月16日お知らせ展示会情報FOOMA JAPAN 2025 国際食品工業展に出展します

- 2024年5月30日お知らせ展示会情報FOOMA JAPAN 2024 国際食品工業展に出展します

- 2023年5月19日お知らせ展示会情報FOOMA JAPAN 2023 国際食品工業展に出展します

- 2023年1月17日お知らせ第9回 ものづくり日本大賞 九州経済産業局長賞を受賞しました

- 2023年1月17日お知らせ令和4年度 宮崎中小企業大賞を受賞いたしました

- 2022年4月28日お知らせ展示会情報機械紹介FOOMA JAPAN2022に出展します

独自設計の機械で製造業のムダやロスをカット。

人件費ダウンにつながる機械をご提案いたします。

工場内生産機械ならマトヤ技研工業にお任せください。

事業概要

各種オーダーメイド対応も承ります。

製品動画

独自設計開発のオリジナル食肉用機械を動画でご紹介いたします。

その他の動画は 全ての製品情報を見るよりご覧ください。

私たちの強み

私たちマトヤ技研工業株式会社は、

①開発から納入(設計・電気設計・加工・組立・現地工事)までを自社で行うことができる一貫性

②自動化・省力化のアイディアを形にする独創性

③納入後のアフターフォロー

を強みに持つセットメーカーです。

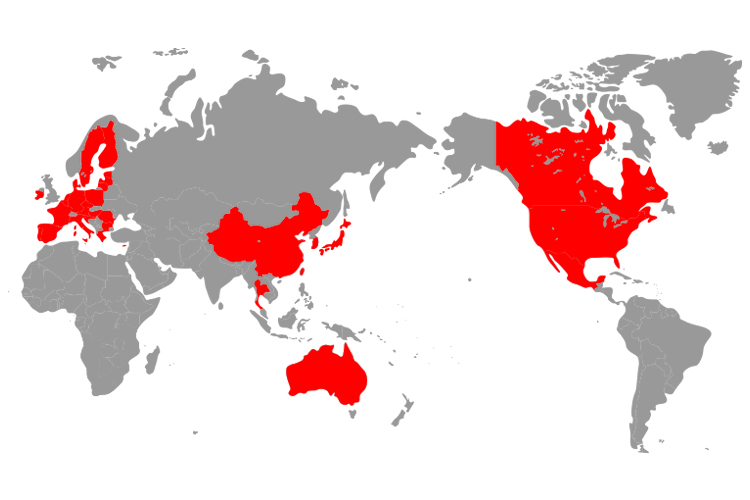

日本国内をはじめ、アメリカ・カナダ・台湾・タイ・中国・EU諸国・メキシコ・オーストラリアなどの海外企業での採用実例も多く、企業様のニーズに応えることのできる提案内容に評価をいただいています。

マトヤ技研工業株式会社は、製造業の省力化・自動化・品質の均一化を支えるシステムの企画・製造を使命とし、各種サービスをご提供し続けて参ります。

ご挨拶

TECHNOLOGY

HIGH

POWER

夢・想像は創造の源

昭和60年夏がマトヤ技研の始まりでした。私達3人(マスドメ・トヨマス・ヤマウチ)はそれぞれの名前の頭を採って屋号を「マトヤ技研」としました。創業以来絶えることなく一貫しているのは「創造」です。日本の片田舎から世界に通用する商品を生み出し、「小さな大企業」と言われるのが私達の夢でした。

お客様のご理解とご支援を頂いて、オリジナル商品も幾つか国内、国外でも評価をして頂けるようになりました。 お客様の立場に立って見つめ、安心して使って頂ける機械装置を提供する事、一緒に働く社員の幸福の達成、更に健全経営を推進して社会から支持され、信用される会社が私達の経営理念であります。 時代は日々変遷して、新たなニーズが生まれて参ります。 私達はこれまでに培って来たメカトロニクス技術を駆使して、新たなニーズに多角的に挑戦を続けて参りました。 今後とも、終わりの無い技術への挑戦を留まることなく続け、一歩づつ前進してこの分野ではオンリーワンと言われる商品開発を目指して参ります。 人口減少社会に向かい市場縮小の時代でも生き残って行ける道をグローバルに探し、人類が生き延びて行ける社会と共存して参ります。 今後とも相変わらぬお引立ての程、宜しくお願い申し上げます。

お客様のご理解とご支援を頂いて、オリジナル商品も幾つか国内、国外でも評価をして頂けるようになりました。 お客様の立場に立って見つめ、安心して使って頂ける機械装置を提供する事、一緒に働く社員の幸福の達成、更に健全経営を推進して社会から支持され、信用される会社が私達の経営理念であります。 時代は日々変遷して、新たなニーズが生まれて参ります。 私達はこれまでに培って来たメカトロニクス技術を駆使して、新たなニーズに多角的に挑戦を続けて参りました。 今後とも、終わりの無い技術への挑戦を留まることなく続け、一歩づつ前進してこの分野ではオンリーワンと言われる商品開発を目指して参ります。 人口減少社会に向かい市場縮小の時代でも生き残って行ける道をグローバルに探し、人類が生き延びて行ける社会と共存して参ります。 今後とも相変わらぬお引立ての程、宜しくお願い申し上げます。

環境保護活動

弊社では、環境保護活動の一環としてエコアクション21の認証取得に取り組んでおります。

様々な環境保護活動を行っています。

お問い合わせ

お電話でのお問い合わせ

0986-76-0018

8時~17時(土・日・祝日を除く)

食肉加工の現場のコスト削減

設備投資で工場の人件費を減らしたい

加工技術の均一化を目指したい

そんな事業者様のお悩みを私たちが解決します。